Space Assembly & Test Facilities

UASI offers state-of-the-art testing facilities and capabilities, centered within the Applied Research Building (ARB). Designed to meet the rigorous requirements of internal teams, external clients, and research partners, these facilities support critical testing for aerospace applications.

The ARB features advanced thermal vacuum chambers for simulating the extreme environmental conditions of space, enabling spacecraft and instrument testing under high-fidelity thermal and vacuum conditions. Our dynamics and vibration testing facilities, including precision vibration and shaker tables, are tailored to assess structural integrity and mechanical performance under simulated launch and operational stresses. Additionally, the anechoic chambers provide cutting-edge EMC and antenna measurement testing, ensuring compliance with electromagnetic compatibility standards and accurate antenna performance evaluation.

These assembly, integration, and test facilities are available to both internal and external users. For detailed specifications, pricing, and scheduling inquiries, please contact us at the email below.

For more information, please email: space-institute@arizona.edu

Thermal Vacuum Testing

Our vacuum test chambers simulate space environments, replicating conditions such as vacuum, extreme temperatures and radiation to test the performance, durability and reliability of telecommunication satellites, spacecraft subsystems and other space-bound technology.

Dynamics and Vibration Testing

Dynamics and vibrations testing simulates mechanical stresses and assesses the effects of controlled vibrations on products to identify structural weaknesses, evaluate durability, optimize designs and ensure resilience in various operational environments, including extreme conditions in space.

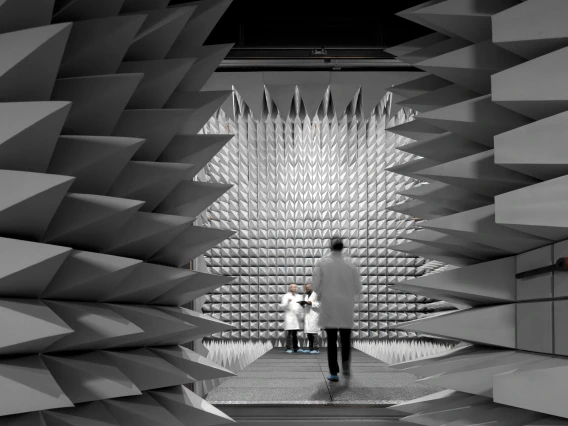

EMC and Antenna Measurement Testing

Our anechoic chamber is used for Electromagnetic Compatibility (EMC) and antenna testing by providing an environment free from external electromagnetic interference to enable accurate measurement of a device's electromagnetic emissions and susceptibility, while its radio frequency isolation ensures precise assessment of antenna performance.